Our Process

Our Process

You dream it.

We create it.

At Metro Vancouver Polished Concrete, we specialize in transforming ordinary concrete floors into stunning, high-performance surfaces. Our expert team of MVPs leverages state-of-the-art techniques and premium materials to deliver exceptional results that will enhance both the aesthetics and functionality of your space.

Surface Inspection and Preparation

The process of achieving a flawless polished concrete floor begins with a meticulous inspection of your existing concrete surface. We assess the area for any cracks, stains, or imperfections that could affect the final finish. If we discover any cracks or holes, we utilize high-quality patching compounds to repair them, ensuring the surface is smooth and flat. This crucial preparation step is foundational, setting the stage for a long-lasting, visually appealing polished concrete floor that will withstand the test of time.

Initial Grinding

With the surface prepared, we move on to the grinding phase, employing top-of-the-line equipment designed for efficiency and precision. This process involves multiple grinding passes to remove the top layer of the concrete, effectively eliminating surface imperfections such as minor pitting, surface stains, and any remnants of old coatings or mastics. Our high-performance grinders gradually refine the surface, revealing a fresh layer of concrete that is both smooth and even. Depending on the floor's condition and your desired finish, we carefully adjust the number of grinding passes to strike the perfect balance between durability and aesthetic appeal, ensuring a stunning outcome tailored to your specific needs.

Finer Grinding

Once the concrete has been ground to the appropriate level, we start the honing and polishing process—a transformative stage that brings your flooring vision to life. We perform several stages of honing and polishing, utilizing progressively finer diamond abrasives to achieve the finish you desire. Whether your preference leans toward a soft, satin matte look or a high-gloss, mirror-like shine, we can customize the polishing process to meet your specifications. Each polishing stage enhances the floor's natural reflectivity, revealing its inherent beauty while providing a smoother, more resilient surface that will impress for years to come.

Sealing and Hardening

Our proprietary sealing process penetrates deep into the concrete, hardening the surface and creating a robust barrier against stains, spills, and wear. This advanced technology not only enhances durability but also protects against moisture and environmental damage by filling in microscopic pores and imperfections. Additionally, the penetrating sealer enriches the concrete's appearance, providing a glossy finish that highlights its natural beauty. This protective layer significantly reduces maintenance efforts, ensuring that your polished concrete floors remain resilient and visually appealing for years to come.

Final Polishing and Finishing

The final step involves using the finest diamond abrasives to meticulously achieve the desired level of polish. This precision polishing process allows us to refine the surface to your exact specifications, ensuring a flawless finish. We can customize the sheen to match your specific requirements, whether you prefer a soft, matte appearance that exudes understated elegance or a high-gloss look that creates a striking, reflective surface. Our attention to detail during this stage not only enhances the visual appeal of your flooring but also contributes to its durability, making it a stunning and practical choice for any space.

Finishes and Aggregate

Exposure Options

Cream Polish

A cream polish is a finishing technique that maintains the concrete's very top layer, known as the "cream."

This method results in a smooth surface with minimal exposure of the underlying aggregate. The finished surface showcases a uniform and polished look with a subtle, natural variation in the concrete's color. This type of finish is ideal for modern residential and commercial interiors where a minimalist and clean aesthetic is desired, as it creates a refined and contemporary appearance.

Salt and Pepper

The salt and pepper finish involves grinding down the concrete surface just enough to expose the fine aggregates, like sand, beneath the top layer. This process creates a surface with a speckled appearance, resembling the look of salt and pepper. The finish offers a more textured and visually interesting surface compared to a cream polish while maintaining a relatively smooth feel. It offers a balance between subtle texture and sophistication, making it suitable for both residential and commercial spaces that desire a bit more character in their flooring.

Heavy Exposed Aggregate

A heavy exposed aggregate finish takes the grinding process deeper into the concrete, revealing large pieces of aggregate, such as stones and gravel, embedded within the mix. The result is a highly textured, rugged surface with significant visual contrast because of the prominent exposure of these aggregates. This finish has a bold, industrial aesthetic, which makes it a popular choice for outdoor areas like driveways, walkways, and patios, as well as for interiors where a dramatic, statement-making look is desired.

Dream in Colour

Make your floors pop with colour and bring your creative visions to life with our spectrum of gorgeous colour options.

Features:

► Non-toxic

► Non-flammable

► VOC-compliant

► Will not peel or flake

► No need to neutralize

► Contains no harmful acids

► Suitable for use in occupied spaces

► Adds colour and depth to diamond-polished concrete

► Produces consistent, gem-like color on any age concrete floor

► Will not etch polished concrete surfaces or corrode surrounding metals

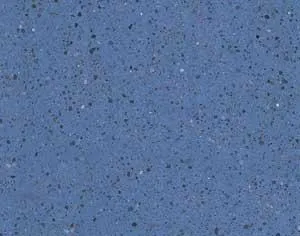

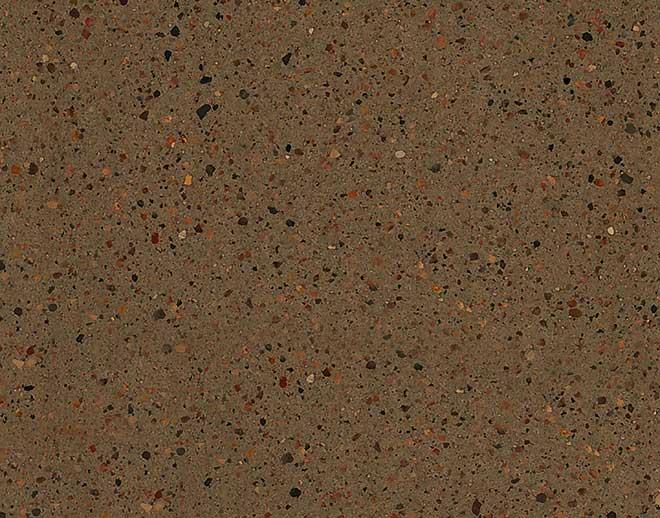

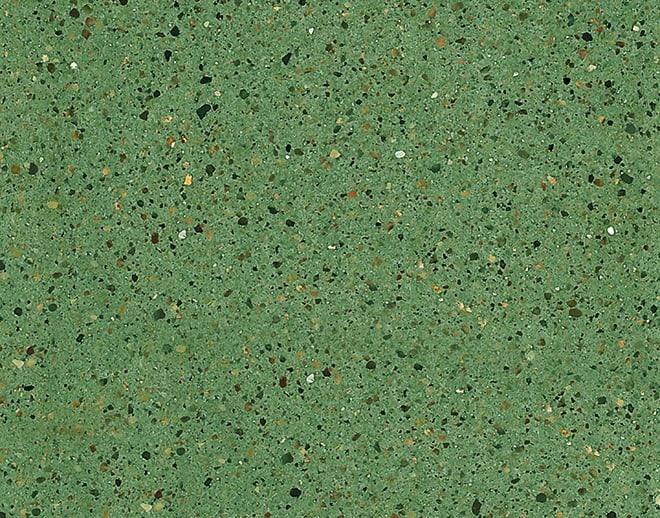

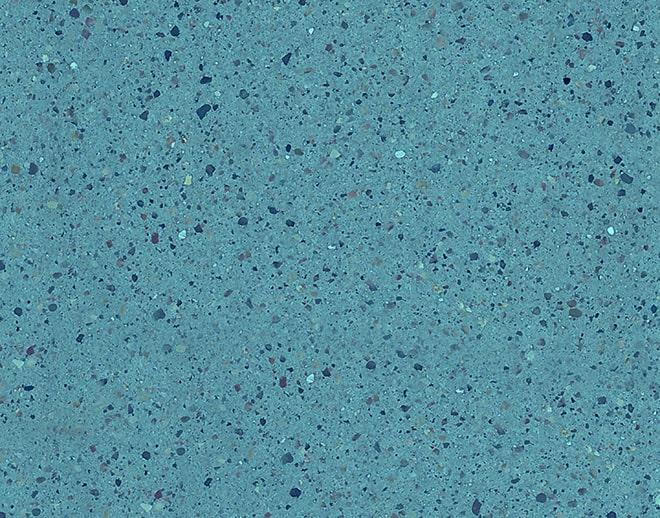

Colour Dye Options

Stenciled Art & Logos

Get creative with the

colour options

Capture the attention of your visitors from the moment they walk in

Benefits of Polished Concrete

Durability: Polished concrete is incredibly durable and resistant to wear and tear, making it ideal for high-traffic areas

Aesthetics: The unique, natural beauty of polished concrete can add a touch of elegance and sophistication to any space.

Low Maintenance: Polished concrete is easy to clean and maintain, reducing the need for costly floor coverings or frequent cleaning.

Increased Value: Polished concrete can significantly increase the value of your property.

Sustainability: Our process is environmentally friendly, using minimal chemicals and reducing waste.

When is the best time to plan my floor finish

on a new construction?

The best time to plan your floor finish for a new construction project is during the early stages of the design phase. This allows MVP Concrete to coordinate with your builder and ensure the flooring is integrated seamlessly into the construction timeline.

For polished concrete, it’s important to consider factors like the floor flatness, level of the slab, the placement of joints, and the type of concrete mix, including integral colours or custom aggregates. By planning ahead, we can help avoid costly issues down the road and make sure you get the floor of your dreams.

After the concrete slab has been poured, the ideal time to begin polishing is

after the concrete has fully cured, typically around 28 days. During this period, it’s crucial to protect the slab from damage caused by heavy construction activity. Scratches, stains, or dents can affect the final finish, so proper protection is key. Additionally, it’s best to complete other trades like drywall, electrical, and plumbing before we finish the floors, minimizing the risk of damage.

The type of flooring protection you use will have an impact on the end result of the polish. Areas that are covered will cure slower and tend to be darker, areas that are left open will appear lighter. This means that if you tape anything to the floor, the tape lines are likely to be visible in the finished polish.

Why does MVP Concrete stand out in the industry?

Expertise: Our team has 12 years of experience in polished concrete installation and restoration.

Quality: We use only the highest quality materials and equipment to ensure exceptional results.

Customer Satisfaction: We are committed to providing exceptional customer service and exceeding your expectations.

Fully Insured: This one seems like a no brainer, yet, many companies operate without insurance. When you work with us, your peace of mind is our top priority.

Communication: When you hire us to work on your project, you won't be guessing what part of the process we are working on, or if the dead line will be met, we make sure that you are up to date with everything related to the project, no ugly surprises here.

Frequently Asked Questions

FAQ

WHY IS POLISHED CONCRETE A BETTER OPTION OVER OTHER FLOORING TYPES IN VANCOUVER'S CLIMATE?

Durability: Polished concrete is highly resistant to wear and tear, making it ideal for Vancouver's heavy foot traffic and varying weather conditions.

Low Maintenance: Unlike other flooring types, polished concrete requires minimal upkeep, reducing maintenance costs and downtime.

Moisture Resistance: Vancouver's humid climate can be challenging for some flooring materials. Polished concrete is naturally moisture-resistant, preventing mold and mildew growth.

Sustainability: Concrete is a natural, renewable resource, making it a sustainable choice for flooring.

IS POLISHED CONCRETE SUITABLE FOR BOTH RESIDENTIAL AND COMMERCIAL SPACES IN VANCOUVER?

Yes. Polished concrete can be customized to suit various styles and functional needs, making it a versatile option for both residential and commercial settings. In residential spaces, it can add a modern and industrial touch, while in commercial settings, it offers a durable and low-maintenance solution.

IS POLISHED CONCRETE SLIPPERY?

No, even when it has a glossy finish concrete actually provides a good level of foot traction and actually fares better than some other flooring choices such as lino or marble. Our sealers offer a good level of additional slip resistance to concrete floors too although, as you would have to with any other flooring material,

WHAT ARE THE BENEFITS OF POLISHED CONCRETE OVER OTHER FLOORING TYPES?

Polished concrete is incredibly durable, versatile and low maintenance. It works incredibly well with underfloor heating and what we like most about it - no two floors are the same.

WHAT ARE THE BENEFITS OF POLISHED CONCRETE FOR INDUSTRIAL APPLICATIONS?

Polished concrete offers numerous advantages for industrial applications in Vancouver. Its non-slip surface significantly reduces the risk of accidents, enhancing workplace safety. Additionally, the smooth surface facilitates easier cleaning and maintenance, minimizing downtime and boosting productivity. The material's resistance to various chemicals and industrial substances makes it suitable for a wide range of applications. Moreover, its durability and low maintenance requirements contribute to significant long-term cost savings compared to other flooring options.

DOES POLISHED CONCRETE STAIN?

Polished concrete is not impervious to damage although concrete stains only usually occur when an accidental spill has been left to sit on the concrete surface for an extended period of time. With regular low-stress maintenance this can be avoided in most cases. As standard, we will always apply a stain-guard sealer on your concrete after it has been polished to make it relatively stain resistant. This sealer will repel spills and give you ‘reaction time’ with which to discover and clean the spill. If left for a number of hours, the sealer can be penetrated and stains can appear.

HOW DO YOU KEEP POLISHED CONCRETE FLOORS SHINY?

We recommend introducing a low stress maintenance routine to keep polished floors shiny and clean. This essentially consists of dry mopping daily to remove dust and grit brought in from outside and a regular wet mop using a PH neutral cleaner. For special occasions, you can also go over the surface with a high-speed burnisher - these machines can be affordable and easy to find for hire. The heat and friction burnishing causes can restore the surface sheen on a well-used floor.

HOW DOES POLISHED CONCRETE COMPARE TO OTHER POPULAR FLOORING OPTIONS LIKE HARDWOOD OR TILE?

Durability: Polished concrete is significantly more durable than hardwood or tile, making it a better choice for high-traffic areas.

Maintenance: Polished concrete requires less maintenance than hardwood or tile, saving time and money.

Cost: While the initial cost of polished concrete may be higher, its long-term durability and low maintenance requirements often result in lower overall costs.

Aesthetics: Polished concrete offers a unique and modern aesthetic that can complement various design styles, making it a desirable choice for many homeowners and businesses.

MVP Concrete specializes in polished concrete flooring, surface preparation, and overlay systems across Vancouver and the Lower Mainland. We deliver durable, low-maintenance solutions for residential, commercial, and industrial spaces—built with precision, integrity, and long-term performance in mind.

Contact Us

Metro Vancouver Polished Concrete

2405-7178 Collier Street, Burnaby BC V5E 4N7

Connect

© Metro Vancouver Polished Concrete 2025

All Rights Reserved